News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.

HEDELIUS Maschinenfabrik has once again received an order to supply two automated 5-axis machining centres from the ACURA series. The automation is realised by an EROWA ERD 250 linear robot. The entire system is 20 metres long and has 73 pallet stations and 520 tool stations.

With this certificate, Creditreform Leer once again attests to the company's excellent creditworthiness. The company continues to fulfil the high requirements for an extension of the CrefoZert in full. Compared to the previous year, the creditworthiness index was even slightly improved from 108 to 106.

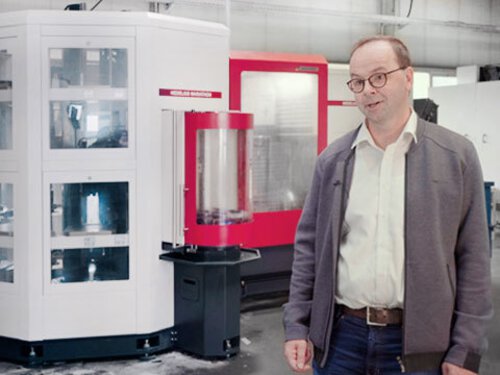

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.

Constant ambient conditions are required to achieve consistent production results. To achieve maximum accuracy and reproducible results, it is important that the temperature of the workpiece remains constant during processing.

In order to make even better use of the output of our machining centres, the TILTENTA 9, TILTENTA 11 and ACURA 85 series will in future have milling spindles with 37 kW output.

The C axis of our 5-axis machining centres in the ACURA 65 series can now be equipped with a liquid-cooled and backlash-free torque direct drive with 50 rpm. The result: the C axis positions with even greater repeat accuracy, acceleration and speed.

"We at WVG Alu tec from Bad Arolsen have known HEDELIUS for many years and are already something of a family. And where do you trust each other more than within a family?" That's why Gruhs is proud of the "latest achievement", as he puts it: the TILTENTA 7-3200 5-axis machining centre with swivelling spindle and two integrated NC rotary tables.